List of equipment

04.02.2026 08:40

Machines | Press machines Press machines

INO Print SA S2-70

| Reference number: | IMP2042 |

| Manufacturer: | INO |

| Model: | Print SA S2-70 |

| Year of production: | 2011 |

| Format / Working width: | 70 x 50 cm |

| Available: | takoj |

| Machine visible: | v proizvodnji |

Technical specification

Automatic Screen Printing Line consisting of:

- Ino Print SA S2-70 (2011) - Automatic Screen Printing Line

- Ino Powder 500 MPA (2016) - machine for sprinkling thermo powder

- Ino Dryer S2-2 V 700 (2012) - hot tunnel with conveyor belt

- Ino S70-B (2009) - automatic delivery

Heidelberg SM 52-2P NP

| Reference number: | IMP2079 |

| Manufacturer: | Heidelberg |

| Model: | SM 52-2P NP |

| Year of production: | 1997 |

| Condition: | good working condition |

| Press / Working hours: | 54 mio. |

| Format / Working width: | 37 x 52 cm |

| Colors / Number of units: | 2 |

| Available: | immediately |

| Machine visible: | in produktion |

Technical specification

- Perfector 2/0-1/1

- with N+P

- Autoplate

- Alcolor dampening

- Technotrans cooling and circulation

- stream feeder

- powder spray

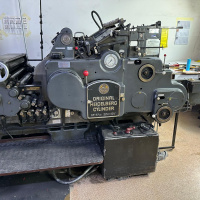

Heidelberg SORMZ

| Reference number: | IMP2063 |

| Manufacturer: | Heidelberg |

| Model: | SORMZ |

| Year of production: | 1990 |

| Press / Working hours: | 90 mio. |

| Format / Working width: | 52 x 74 cm |

| Colors / Number of units: | 2 |

| Available: | takoj |

| Machine visible: | v proizvodnji |

Technical specification

- Stream feeder

- Alcolor dampening

- Chiller unit

- Quick Action Plate Clamps

- Chrome Impression and plate Cylinders

- Grafix Powder Spray

- Low Pile Delivery

- CPC working desk

Roland Favotiz RZFOB

| Reference number: | IMP592 |

| Manufacturer: | Roland |

| Model: | Favotiz RZFOB |

| Year of production: | 1986 |

| Press / Working hours: | cca 47 mio. |

| Format / Working width: | 52 x 72 cm |

| Colors / Number of units: | 2 |

| Available: | immediately |

| Machine visible: | in produktion |

Technical specification

- no. 17166b, serie 640

- Mabeg Feeder

- Rolandmatic dampening with refrigeration system

- High pile delivery

- Powder spray Grafix Exactomat

Heidelberg PM 74-4P

| Reference number: | IMP2066 |

| Manufacturer: | Heidelberg |

| Model: | PM 74-4P |

| Year of production: | 2006 |

| Press / Working hours: | cca. 100 mio. |

| Format / Working width: | 52 x 74 cm |

Technical specification

- perfecting system - 4/0 - 2/2

- CPC 1.04

- Alcolor dampening

- Autoplate

- Technotrans cooling and circulation

- ink temperature control

- automatic washing systems

- low pile delivery

Heidelberg SM 52-4+L

| Reference number: | IMP2080 |

| Manufacturer: | Heidelberg |

| Model: | SM 52-4+L |

| Year of production: | 2002 |

| Press / Working hours: | cca. 130 mio. |

| Format / Working width: | 37 x 52 cm |

Technical specification

- Straight machine

- CP 2000

- Autoplate

- Alcolor dampening

- Cooling and circulation

- Automatic impression cylinder, blanket cylinder and ink roller washing systems

- Coating Unit

- Powder spray

- High pile delivery

- Extended delivery (X1)

Ryobi 784 EP

| Reference number: | IMP2065 |

| Manufacturer: | Ryobi |

| Model: | 784 EP |

| Year of production: | 2010 |

| Press / Working hours: | cca. 80 mio. |

| Format / Working width: | 52 x 74 cm |

Technical specification

- Perfecting: 2/2 – 4/0

- Semi-APC

- Ryobi-matic dampening

- Ryobi-ink-remote-control

- Preset

- Stream-feeder

- CIP 3

- Densitometer

- Automatic correction

- Automatic washing systems

Heidelberg SM 74-5-P-H

| Reference number: | IMP2053 |

| Manufacturer: | Heidelberg |

| Model: | SM 74-5-P-H |

| Year of production: | 1999 |

| Press / Working hours: | cca. 196 mio. |

| Format / Working width: | 52 x 74 cm |

Technical specification

- Perfector 2/3 - 5/0

- CPC 1-04

- CP-Tronic

- Autoplate

- Alcolor dampening

- Tehnotrans cooling and circulation

- Grafix Alphatronic 200

- Automatic washing systems

- High pile delivery

- IR dryer

INO automatic stacking device STACKER AS1 500

| Reference number: | IMP2062 |

| Manufacturer: | INO automatic stacking device |

| Model: | STACKER AS1 500 |

| Year of production: | 2017 |

| Format / Working width: | working width max 500 mm |

| Available: | immediately |

| Machine visible: | stock |

Technical specification

Automatic stacking device STACKER AS1 500

Automatic sheet stacker to collect printed and dried sheets from the outlet of the conveyor dryer; alignment and piling up of the sheet substrates.

Automatic alignment of sheets, approaching from the dryer outlet

Detection of the leading sheet edge, gripping and pulling the sheet onto pile – no scratching of the forerunning sheet

Pile flaps for sheet edge alignment

Anti-static discharge bar

Technical data of STACKER AS1:

Max. sheet infeed rate to 1000 pcs/h

Inlet shelf height 940 ±25 mm

Max. pile height 35 mm

INO POWDER MPA 500 - melt powder application machine

| Reference number: | IMP2060 |

| Manufacturer: | Melt powder application machine INO |

| Model: | POWDER MPA 500 |

| Year of production: | 2017 |

| Format / Working width: | max sheet width 500 mm |

| Available: | immeditaely |

| Machine visible: | stock |

Technical specification

Melt powder application machine POWDER MPA 500

- Anti-static conveyor belt to maintain a smooth sheet transport with uniform powder coat application

- Frequency controlled motors with variable drive speed

- Dual vacuum extraction system, acting from top and bottom of the passing sheet, to provide highly-effective removal of excess powder

- Quick change-over between different powder types

- Preset parameters for application of different powder types

- Laser sensors, reading the sheet pass – for continuous operation or »start & stop« application mode

- Brush roller on exit

Technical data:

- max sheet width 500 mm

- conveyor belt width 540 mm

- max material thickness 2 mm

- powder range 80 - 200 μm with antistatic treatment

- conveyor belt height 940 ±25 mm

- conveyor belt speed 0 – 10 m/min

INO PRINT VS6 500

| Reference number: | IMP2058 |

| Manufacturer: | INO |

| Model: | PRINT VS6 500 |

| Year of production: | 2021 |

| Format / Working width: | 500 x 350 mm |

| Available: | immediately |

| Machine visible: | in production |

Technical specification

- 3/4 used automatic screen printing machine PRINT VS6 500

The PRINT VS6 is modernly designed screen printing machine for printing on different materials (foil, paper, cardboard, self-adhesive material etc.) on vacuum table.

Easy handling, swift tool exchange, fine regulation of all for printing important parameters are just some of the equipment highlights.

- Automatic take-off device

increases productivity up to 30% and print quality as well as renders operator’s service easier as he only takes care to load printed materials. Take-off could be performed from any position of the vacuum table.

- Servo drive of lifting system

servo drive saves expensive air consumption.

screen retraction when loading is adjustable up to 450 mm.

max printing object height is 400 mm.

- Automatic positioning on vacuum table on previous digital print

- Technical data of PRINT VS6 500:

max. sheet format 500 x 350 mm

max. print format 495 x 330 mm

material thickness For automatic off-loading: up to 2 mm

for manual off-loading: up to 400 mm

max. screen dimension 900 x 700 mm

screen frame height 30 - 40 mm

Vacuum table height 950 ±25 mm

Machines | Postpress machines Postpress machines

Perfecta 115 TVC

| Reference number: | IMP2070 |

| Manufacturer: | Perfecta |

| Model: | 115 TVC |

| Year of production: | 2002 |

| Format / Working width: | 115 cm |

Technical specification

- working width 115 cm

- standard display

- airtable

- side tables left and right

- photo cells

Polar 115 EM-MON

| Reference number: | IMP2071 |

| Manufacturer: | Polar |

| Model: | 115 EM-MON |

| Year of production: | 1992 |

| Format / Working width: | 115 cm |

Technical specification

- Working width 115 cm

- Digital programs

- Basic air table

- Air tables left and right

- Other standard equipment

- Photocells security system

Kolbus KM 600

| Reference number: | IMP2077 |

| Manufacturer: | Kolbus |

| Model: | KM 600 |

| Year of production: | 2015 |

| Press / Working hours: | only cca. 23 mio. products |

Technical specification

- Kolbus XMT 280 bookbloc feeder with infeedbelt

- Handfeeding station

- 16 stations gatherer ZU805

- Signature recognition system

- Reject delivery

- Infeed into binder

- Milling station

- 2 spine preparation units

- Hotmelt spine gluing with premelter

- Hotmelt side gluing

- PUR nozzle glue system with Nordson PUR Premelter

- WST glue measuring control system

- Gauzing station

- Pile cover feeder RA49A

- 2 nipping stations

- Laydown delivery

- Conveyor system with dry tower

- Kolbus FA650 front cut machine

- Kolbus HD143P three knife trimmer

- Kolbus KL301 compensating stacker

- Measuring table MT600

- AFS 3.60

- Becker air center

MKW RAPID UT / B3 / GS + MKW RAPID SFT 350

| Reference number: | IMP2039 |

| Manufacturer: | MKW |

| Model: | RAPID UT / B3 / GS + MKW RAPID SFT 350 |

| Year of production: | 2025 |

| Format / Working width: | 35 x 50 cm |

| Colors / Number of units: | 16 |

Technical specification

MKW RAPID UT / B3 / GS / RL + MKW RAPID SFT 350

New automatic collator MKW RAPID UT16 / B3 / GS

- 16 stations

- Paper format: 10 x 14 cm to 35 x 50 cm

- High pile up to 70 cm

- Paper weight up to 1000 g/m²

- Materials: single sheets, folded sheets, carton, plastic foils...

- Missing and double sheet control

- Automatic missing sheet retry function

- Ejector unit

- Right (brochures) & Left (calender, blocks…) movement direction

- Additional collating functions (Tandem)

Stitching, folding and front trimming unit MKW RAPID SFT 350 (factory refurbished)

- Brochure open format: 10 x 14 cm to 35 x 50 cm

- Quick format setting

- 2 flat-staple stitching heads Hohner HK 43/6 FL (possible to connect up to 6 stitching heads)

- Folding unit

- Front trimming unit – min. lenght 6 cm

- Brochure delivery with electronic separator

Options:

Head and tail trimming unit MKW RAPID T 20 (factory refurbished)

- Min. brochure format: 10 x 6 cm

- Max. brochure format: 35 x 25 cm

High pile delivery MKW RAPID HA-350 L (on left side)

- Format 10 x 14 cm to 35 x 50 cm

- Loading capactiy up to 60 cm

- Stacking function adjustable: straight stacking or offset function

- 2 movable stagger pallets

THE MACHINE PICTURES ARE SAMPLE!

Horizon ST-40

| Reference number: | IMP2014 |

| Manufacturer: | Horizon |

| Model: | ST-40 |

| Year of production: | 2009 |

Technical specification

Stacker Horizon ST-40

Kolbus DA 270

| Reference number: | IMP2075 |

| Manufacturer: | Kolbus |

| Model: | DA 270 |

| Year of production: | 2002 |

Technical specification

For fully automatic production of book cases, files, display cards, calendar backs or game boards.

- Motorised setting

- Automatic case counter

- Board pre stacking conveyor

- Centre strip infeed (stiff)

- Centre strip infeed (flexible)

- Waste chopper

- Cloth feeder

- Glue unit

- Preheated glue tube

- Viscosity control

- Device for inside lining with hotmelt

- Device for producing padded cases

- Pressing station

- Stacking delivery

Technical details:

- Size range opened case (min) 205 x 140 mm

- Size range opened case (max) 670 x 390 mm

- Join width: 4 - 15 mm

- Width between boards: 14 - 120 mm

- Turn width, closed 8 - 15 mm

- Cloth with: 223 - 708 mm

- Cloth height: 130 - 428 mm

- Boards thickness: 1 - 4mm

- Board Width: 95 - 328 mm

- Board Height: 140 - 390 mm

VBF Stahl BL 500

| Reference number: | IMP2081 |

| Manufacturer: | VBF Stahl |

| Model: | BL 500 |

| Year of production: | 1997 |

Technical specification

One fully automatic book production line BL 500, consisting of:

1. Core Bookline RHE 525

With centrally selectable automatic adjustment system CAC/COS for the production of case-bound books.

It is possible to process both thread-sewn and adhesive-bound book blocks, with rounded or square spines, and to hang in covers with rounded or square spines.

Machine equipment:

• Electronic measuring system for format input of book block and cover into the CAC/COS system

• Adjustment motors for automatic machine setup

• Timing carriage and continuous chain conveyor system for format-retaining book transport

• Quick-change devices for interchangeable parts

• 1st gluing and gauze station

• 2nd gluing and headband/backlining station

• Pneumatically controlled forming cushions for full-surface pressing of the backlining material

• Numerical input of cutting width for gauze and backlining material

• Stepper motors for precise feeding of gauze and backlining material

• Universal divider for head or foot alignment with block rounding unit

• Cover opening station (DAS)

• Cover forming unit (spine molding), thermostat-controlled up to 300°C, with automatic lowering

• Folding-in unit and glue roller system incl. cleaning trays

• Delivery and infeed conveyor to folding-in and pressing machine EP 608/L

Format Ranges (standard sizes)

Book block:

• Max: 270 × 380 × 75 mm

• Min: 100 × 100 × 5 mm

Finished book:

• Max: 280 × 390 × 80 mm

• Min: 105 × 105 × 5 mm (+ cover thickness)

Opened cover:

• Max: 650 × 390 mm

• Min: 210 × 105 mm

Cover thickness:

• Max: 5 mm

* With special thin-book rounding device (optional): block thickness from 2 mm possible

2. Folding-in and Pressing Machine EP 608/R

For fully automatic pressing-in of hung-in books with uninterrupted, thermostatically and pressure-controlled pressing plates for spine and cover surfaces.

Books are fed from the delivery belt of the core bookline into the EP 608.

Via a distribution table, two books are loaded simultaneously into two pressing stations and unloaded at the delivery station.

This unique and patented technical solution enables a 50% increase in mechanical cycle speed, i.e. 26 cycles at a nominal output of 52 books/min.

EP 608/R – Equipment

• Motor-driven and CAC/COS-controlled automatic adjustment of pressing jaws

• Selector switch for switching on pressing bars

• Selector switch for format adjustment

• Motorized fine correction of machine base setting during operation

• Quick-change devices for pressing bars, forming punches, and prism table

• Selector switch for EP 608 pressing cycle

• Post-forming of rounding and fitting the book block into the cover

• Control lamps for monitoring pressing bar function

• Display and monitoring of all electrical functions on control panel and CAC/COS monitor

• Digital temperature display of thermostatically controlled pressing bars

• Adjustable pressing pressure of jaws and pressing bars

• CE marking (EU standard)

• Certification by German Employers’ Liability Insurance Association

Format Ranges – EP 608/R

Book:

• Max: 300 × 390 × 80 mm

• Min: 80 × 100 × 5 mm

Machines | Packaging machines Packaging machines

Heidelberg Cylinder SBG

| Reference number: | IMP2069 |

| Manufacturer: | Heidelberg |

| Model: | Cylinder SBG |

| Year of production: | 1972 |

| Format / Working width: | 57 x 77 cm |

Technical specification

- for die cutting

- Max. size 57 x 77 cm

- serial number: 37064

Heidelberg Varimatrix 105 CS

| Reference number: | IMP2029 |

| Manufacturer: | Heidelberg |

| Model: | Varimatrix 105 CS |

| Year of production: | 2006 |

| Press / Working hours: | cca. 37.000 h |

| Format / Working width: | 750 x 1050 mm |

Technical specification

- Non-Stop Feeder

- Stripping Unit

- Non-Stop Delivery

- Chases 2x

- Cutting plates; 5mm and 4+1 mm, About 50 – 1 mm plates

- Table for presetting of striping tools

- Largest Sheet Size X : 750 mm

- Largest Sheet Size Y : 1050 mm

- Min. Sheet Size X : 370 mm

- Min. Sheet Size Y : 400 mm

Tecnomac Evolution 76

| Reference number: | IMP2067 |

| Manufacturer: | Tecnomac |

| Model: | Evolution 76 |

| Year of production: | 2008 |

| Format / Working width: | 76 x 104 cm |

Technical specification

- Automatic Feeder

- Electronic Overlap

- Chromed roll heated by fluid

- Pressure rubber roller with pneumatic movement

- Motorized trimming device

- Decurling device

- Automatic separator

- Automatic Stacker

Technical details:

- Maximum format: 76 x 104 cm

- Minimum format: 21 x 21 cm

- Speed: 60 m/min

Machines | Miscellaneous machines Miscellaneous machines

Heidelberg CTP Suprasetter A52 / A75

| Reference number: | IMP2068 |

| Manufacturer: | Heidelberg |

| Model: | CTP Suprasetter A52 / A75 |

| Year of production: | 2018 |

Technical specification

- Approximately 93.000 Plates done

- Gen III

- Prinect Meta Dimension

- Inline punch

- with computer and RIP

- ATL Auto Top Loader

- Glunz & Jensen plate processor

- Glunz & Jensen stacker

Technical details:

- throughput option (Plates/h in max. format): 17/22

- dimensions (width × depth × height): 1,550 × 1,218 × 1,350mm

- min. plate format (height × width): 240 × 240mm

- max. plate format (height × width): 676 × 760mm

- max. imaging area (height × width): 1,413 × 1,460mm

- plate thickness: 0.15–0.3mm

- resolution: 2,400dpi, 2,540dpi

Atlas Copco GX2

| Reference number: | IMP1901 |

| Manufacturer: | Atlas Copco |

| Model: | GX2 |

| Year of production: | 2002 |

Technical specification

Air compressor Atlas Copco GX2

- max. working pressure: 10 bar

- free air deliver: 4 l/s

- nominal shaft power: 2,2 kW

- rotational shaft speed: 1500 r/min

Zünd G3 XL-3200

| Reference number: | IMP2052 |

| Manufacturer: | Zünd |

| Model: | G3 XL-3200 |

| Year of production: | 2018 |

| Format / Working width: | 2270 mm x 3200 mm |

| Available: | 11/2025 |

| Machine visible: | in production |

Technical specification

- Max. working size: 3200 x 2270 mm

- UCT - Drag Knife Tool

- V-Cut Tool

- Creasing Wheel

- Perforation Tool

- Kiss Cut Tool

- Electric Oscillating Tool

- Router Module

- Passive roller for roll materials

- Conveyor belt